Caliper Overseas is a leading Air Valve Manufacturers and Suppliers in India providing superior solutions for industrial and water pipeline system. An air valve is a device designed to release trapped air and maintain a vacuum free environment in the pipelines. It is available in air and vacuum valves, automatic air release valves and combination air valves, each specifically designed to ensure smooth fluid flow while securing the system from pressure problems.

Air Release Valve, Air Control Valve, air valve types, air vent valve, air check valve, Air Valve Supplier In Mumbai, India.

These air valves are renowned for their corrosion resistance, heavy-duty construction, leak-tight operation and long life. They are easy to install, require low maintenance and work even under high pressure. Fast air release and improved system efficiency are ensured by carefully engineered designs. They are ideal for clean water and wastewater applications.

Require effective air valves with long-lasting performance? Call us now!

Automatic Air Valve, Combination Air Valve, Vacuum Air Valve, Air Release Valve, Kinetic Air Release Valve, Saddle Air valve, Air Valve Suppliers, Air Valve Exporter In India.

Air Valve Specification

| Design Standards | ASME B16.34; DIN 3202; BS 5156 |

|---|---|

| Class Range | ANSI 125LB/ 150LB/ PN10/ PN16 |

| Size Range | 50 mm to 200 mm (1/2", 3/4", 1", 2", 3" NPT; 6" #125 Flg) |

| Pressure Rating | PN 10, PN 16 (150 psi, 175 psi, 300 ps) |

| Handling sewage | up to 5000 ppm |

| Temperature Range | Water to 180°F |

| Body and Cover | Ductile Iron ASTM A536 65-45-12 |

| Orifice Button | EPDM |

| External Cover Bolts | ASTM F593 316SS |

| Application & uses | Sewage and Sewage Pipelines Wastewater and wastewater pumping stations Residual and sewage water Municipal and industrial wastewater treatment plants Food Processing, Pharmaceutical and Brewing Systems |

High-Quality Air Valve, Welded End Air Valve, Lift Air Valve, Heavy Duty Air Valve, High Pressure Air Valve, Pressure Balance Air Valve, Industrial Air Valve, Air Valve Stockist In Mumbai.

“View air valve pressure rating, Contact us today to know air valve best offers & prices.”

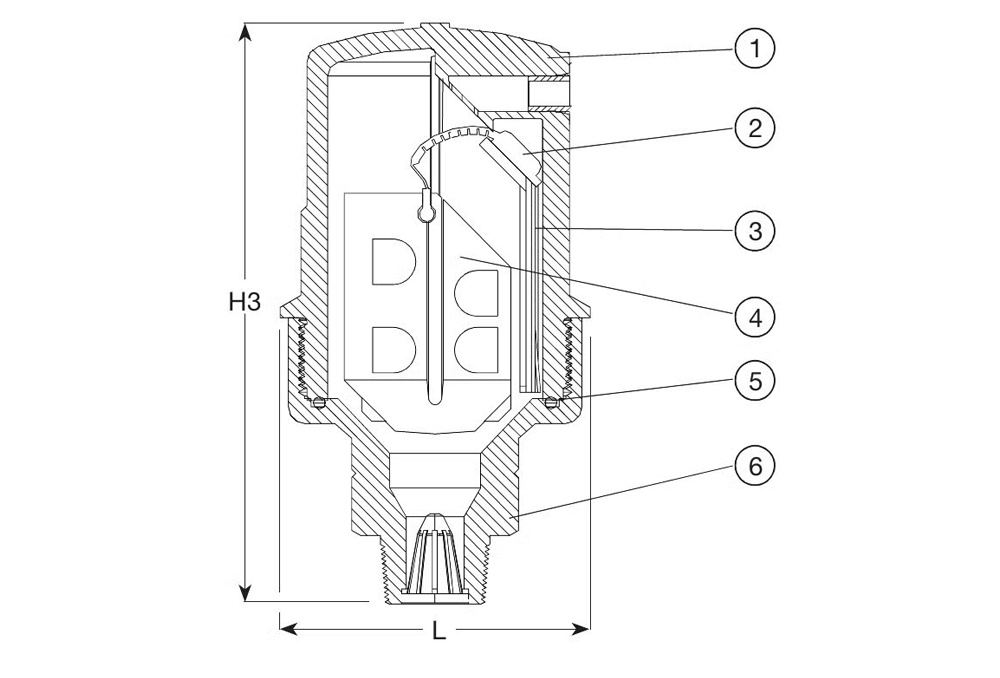

| 1. | Body | PA, reinforced |

| 2. | Rolling seal | EPDM rubber |

| 3. | Clamping key | PA, reinforced |

| 4. | Float | PP |

| 5. | O-ring | NBR rubber |

| 6. | Base | PA / brass |

- Air Valve Manufacturer

- Double Air Valve

- PN16 Air Valve

- Single Chamber Air Valve

- Air Valve Supplier

- Wastewater Air Valve

- Compact Air Valve

- Double Orifice Air Valve

- Compound Lever Air Valve

- Air Valve Stockist In Mumbai

- PN16 Air Valve

- Air Valve Supplier

- Air Valve Supplier In India

- More Durable Air Valves

- Vacuum Breaker Valves

- Wastewater Air Release Valves

- Water Air Vacuum Valves

- Air Valves Manufacturer in India

- Dual Body Air Valves

Air Valves in Distillery Plants

Air Valves in Sugar Industries

Air Valve in Process Industries

Air Valve in Power Plants

Air Valve in Refineries

Air Valve in Petrochemical Plants

Your #1 Source for Air Valve

Malaysia

Malaysia Japan

Japan Russia

Russia UK

UK

Singapore

Singapore Kuwait

Kuwait Italy

Italy Portugal

Portugal Saudi Arabia

Saudi Arabia Australia

Australia Morocco

Morocco United States

United States Qatar

Qatar Germany

Germany China

China Thailand

Thailand India

India Canada

Canada Kazakhstan

Kazakhstan Egypt

Egypt Iran

Iran Philippines

Philippines South Korea

South Korea Vietnam

Vietnam UAE

UAE Oman

Oman Costa Rica

Costa Rica Turkey

Turkey Cyprus

Cyprus Sri Lanka

Sri Lanka Spain

Spain Tobago

Tobago Colombia

Colombia Netherlands

Netherlands Romania

Romania Chile

Chile Poland

Poland Ukraine

Ukraine Mexico

Mexico Tobago

Tobago Myanmar

Myanmar France

France Brazil

Brazil Czechia

Czechia Iraq

Iraq Bangladesh

Bangladesh Nigeria

Nigeria Taiwan

Taiwan Jordan

Jordan Norway

Norway Greece

Greece South Africa

South Africa Hong Kong

Hong Kong Venezuela

Venezuela Indonesia

Indonesia Angola

Angola

Air Valve Stock Availability

Stainless Steel Air Valve

Stainless Steel Air Valve Exporter, PN16 SS Air Valve, Stainless Steel Combination Air Valve, Stainless Steel Air Valve Price, SS Vacuum Air Valve, Stainless Steel Air Valve, SS Automatic Air Valve, Stainless Steel Weir-Type Air Valve, PN10 SS Air Valve, SS Air Valve Supplier, SS Air Valve.

Carbon Steel Air Valve

Carbon Steel Air Valve, Carbon Steel Air Valve Price, PN10 CS Air Valve, CS Air Valve Supplier, Carbon Steel Weir-Type Air Valve, Carbon Steel Air Valve Exporter, CS Automatic Air Valve, Carbon Steel Kinetic Air Valve, PN16 CS Air Valve, CS Vacuum Air Valve, CS Air Valve.

Cast Iron Air Valve

Cast Iron Air Valve, Cast Iron Kinetic Air Valve, Cast Iron Automatic Air Valve, Cast Iron Air Valve Exporter, Cast Iron Air Valve Supplier, Cast Iron Air Valve Price, PN16 Cast Iron Air Valve, Cast Iron Air Valve, PN10 Cast Iron Air Valve, Vacuum Cast Iron Air Valve, Cast Iron Weir-Type Air Valve.

Alloy Steel Air Valve

AS Vacuum Air Valve, Alloy Steel Air Valve Price, Alloy Steel Air Valve Exporter, AS Automatic Air Valve, Alloy Steel Weir-Type Air Valve, PN10 AS Air Valve, AS Air Valve, AS Air Valve Supplier, Alloy Steel Kinetic Air Valve, PN16 AS Air Valve, Alloy Steel Air Valve.