Selecting the appropriate valve is essential for ensuring effective and secure fluid management in industrial processes. The butterfly valve is unique among the many varieties accessible because of its versatility, affordability, and ease of use. This blog will explain butterfly valves and go over their functions, essential components, and typical applications. Having a firm understanding of butterfly valves can help you make informed decisions for the maintenance and performance of your system, whether you work as an engineer, maintenance manager, or in operations.

Know About Butterfly Valves

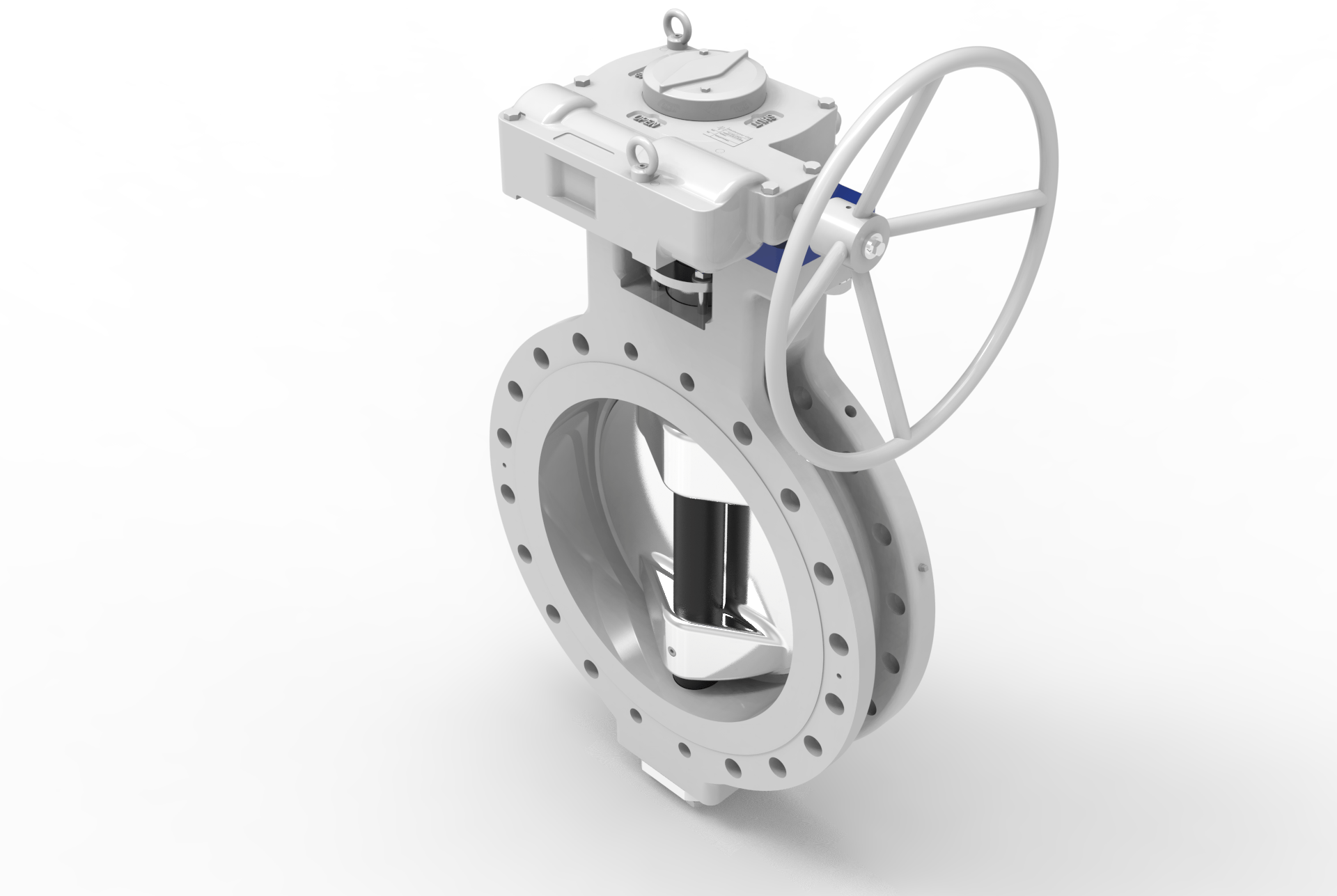

By rotating a disk, a butterfly valve regulates or stops the flow of a fluid—which could be gas, liquid, or slurry—through a pipeline. The flow rate can be managed by this rotation, or it can be completely stopped. Its lightweight, compact design is one of the key characteristics that distinguishes it from other valves, such as ball or gate valves.

Because of this, butterfly valves are the perfect choice in situations where there is a requirement to save weight or space.

How Do Butterfly Valves Operate?

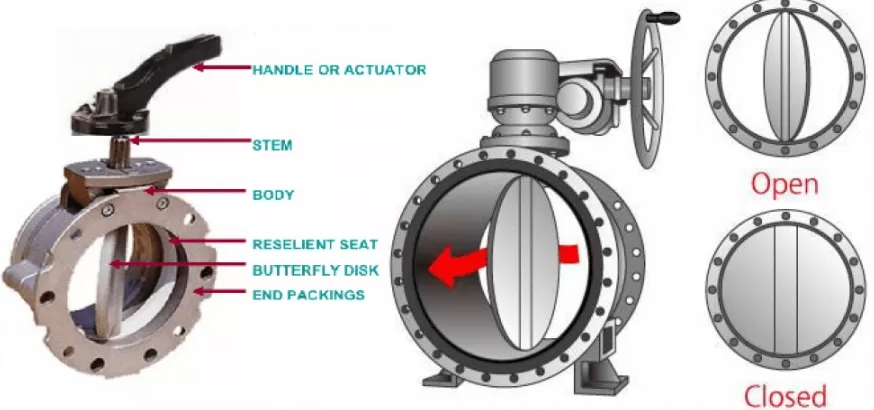

A butterfly valve is easy to operate.

Open Position: The valve’s disc is turned 90 degrees to line with the flow while it is in the open position, allowing fluid to move through with no resistance.

Closed Position: The disc is moved perpendicular to the flow by a 90-degree rotation in the opposite direction, which essentially closes up the pipeline.

Partially Open Position: Precise flow control is possible with butterfly valves since they may be adjusted to any position in between fully open and fully closed. These valves are flexible and can be used in a variety of applications, depending on the particular requirements of the system. They can be operated manually or with the help of pneumatic, hydraulic, or electric actuators.

Key Components of a Butterfly Valve

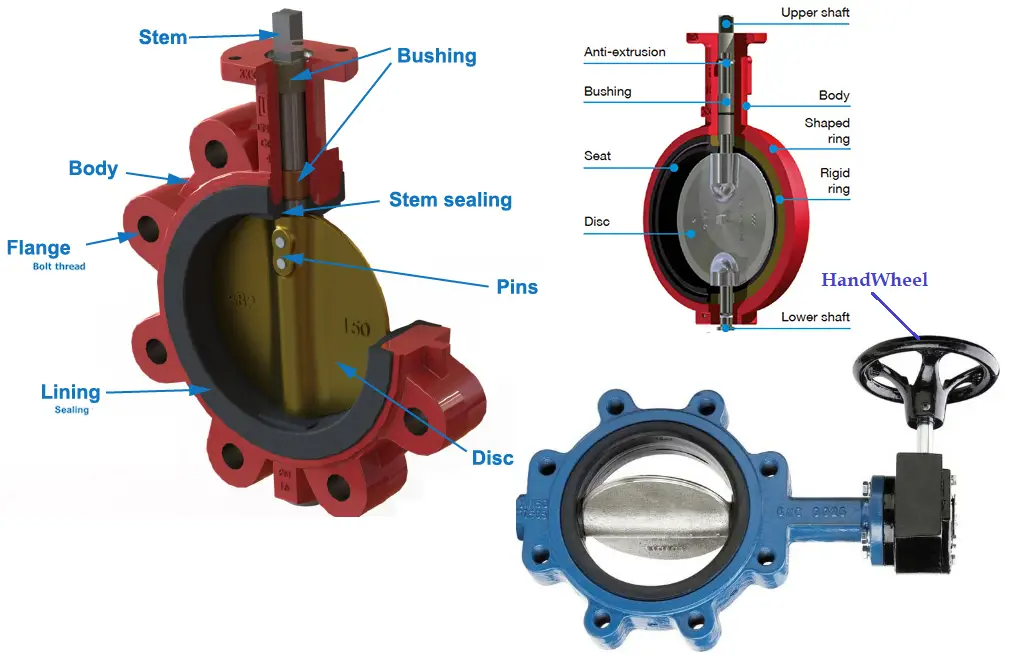

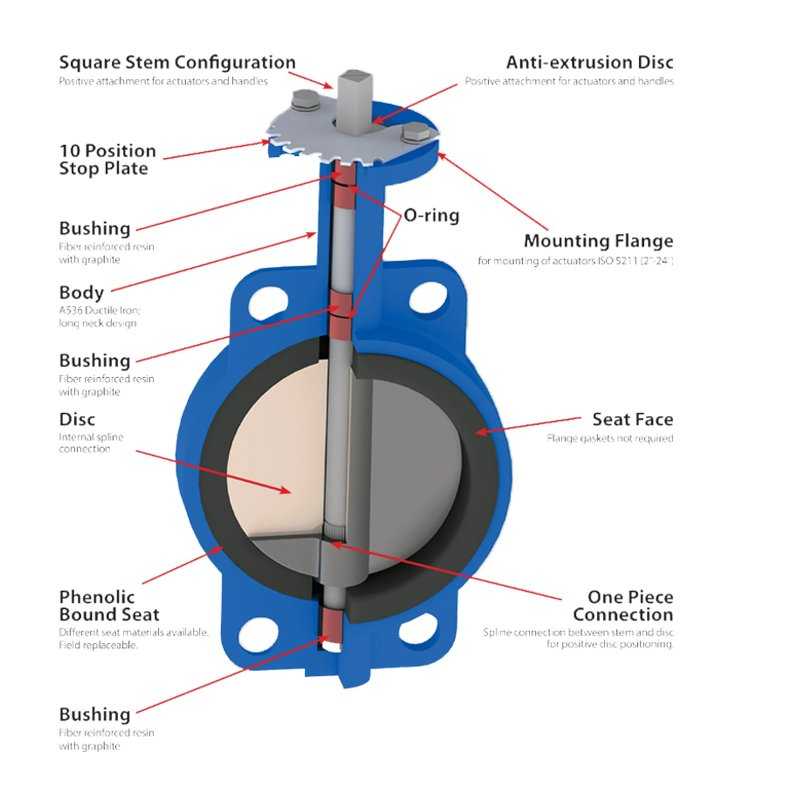

Before you can understand how well these valves work, you need to know about their main parts:

Valve Body: This part goes between the pipe joints and comes in a number of different styles, such as wafer or lug. The wafer type is often used because it is cheap and doesn’t weigh much.

Disc: This is the part that actually controls the flow. The disc’s material and shape are important, especially when working with fluids that are acidic or hot.

Stem (or Shaft): The stem connects the disc to the actuator or hand lift. It can be placed in the middle or off to the side. Most of the time, a central stem is used, but in high-performance settings, offset forms are used.

Seat: The seat makes sure that the disc and the valve body are sealed. Depending on the fluid that needs to be managed, it’s usually made of metal, rubber, or PTFE.

Actuator: The force that turns the disc comes from the actuator. Butterfly valves that are operated by hand use levers or gears, while automatic valves use electric, pneumatic, or hydraulic actuators.

Different Kinds of These Valve

There are three main types of butterfly valves, and each one is best for a certain job:

Concentric (resilient-seated) these valves: A concentrated valve is the most common type, where the disc and stem are centered. This style works best in low-pressure situations.

Double-offset (high performance) these valves: Double off-set valves are when the disc is moved away from the axis, which stops seat wear and makes the valve seal better, especially in systems with higher pressure.

Triple Offset Butterfly Valve (TOV): The triple off-set valve has three offsets that keep the disc from touching the seat until it’s fully closed. This makes for a tight seal that works well in high-temperature and high-pressure situations.

Common Applications of Butterfly Valve

Butterfly valves are useful in many fields because they can be used in different ways. Here are a few important areas of use:

Water and Wastewater Treatment: Butterfly valves control water flow in treatment plants and municipal water systems.

HVAC Systems: These valves help manage airflow in heating, ventilation, and air conditioning systems, particularly in larger buildings.

Chemical Processing: Butterfly valves handle corrosive fluids, making them well-suited for chemical plants.

Power Generation: In power plants, high-performance butterfly valves are used in systems like steam and gas turbines and cooling water systems.

Food and Beverage: Hygienic butterfly valves with specialized seals are commonly used in this industry to control the flow of liquids under sanitary conditions.

Advantages of Butterfly Valve

Some of the best things about butterfly valves are:

Compact Design: Because they are light and small, they are easy to set up even in small areas.

Cost-effective: these valves tend to be less expensive than other types of valves, both when they are first installed and over time as they need less upkeep.

Fast Operation: The quarter-turn design makes it easy to open and close quickly, which is very helpful when time is of the essence.

Low Maintenance: Because butterfly valves have fewer working parts, they usually need less maintenance, which helps them last a long time.

Versatility: They can work with different types of media, such as gases, liquids, and slurries.

Conclusion

Butterfly valves are a quick, easy, and inexpensive way to control the flow of fluids in many fields. They are popular for everything from treating water to handling chemicals because they are small, easy to use, and flexible. By learning about the different kinds of butterfly valves and their parts, you can choose the right one for your needs and make sure that your system works smoothly and reliably.