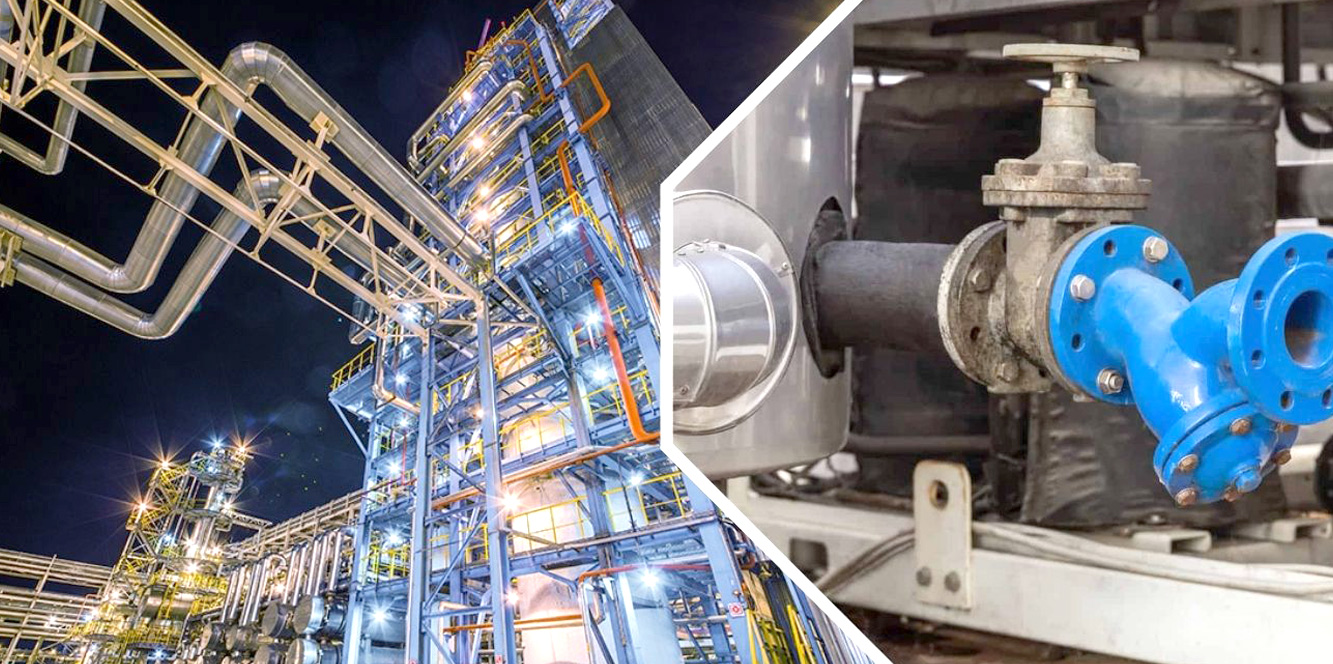

Understanding Strainers in Piping Systems

Strainers play a critical role in piping systems, with a job to filter debris and prevent damage from equipment. They are very important in retaining the efficiency of piping systems and prolonging their service life by acting as pipe filters, promoting smooth operation, and saving maintenance costs. This blog will cover what are strainers, their applications and why they are necessary in various industries.

What is a Strainer in Piping?

A strainer in a piping system is a device used to filter or strain solid particles from a liquid or gas flowing through a pipeline. It is typically placed before pumps, valves, and other sensitive equipment to prevent clogging and damage. The purpose of a piping strainer is to ensure the cleanliness of the fluid, thus maintaining the efficiency and longevity of the entire system.

A strainer makes the fluid pass through a straining element that has very small holes. The smaller the holes, the smaller the solid particles that will be trapped. Strainers come in various types, including Y-strainers, basket strainers, and pot type strainers, each serving a specific role in achieving this purpose.

Explore the best types of strainers for efficiency.

What are Strainers Used For?

Strainers are commonly used in:

- Industrial Applications: Protecting pumps, valves, and heat exchangers from debris in chemical plants, refineries, and power plants.

- HVAC Systems: Ensuring efficient operation and extending the lifespan of heating, ventilation, and air conditioning systems by removing debris from the circulating fluid.

- Water Treatment Plants: Removing debris from water before further treatment, protecting equipment, and ensuring water quality.

Importance of Using a Strainer in Piping Systems

Using a strainer in piping systems is crucial for protecting downstream equipment from damage caused by debris and contaminants in the fluid. By capturing solid particles and preventing them from entering sensitive components, strainers help to maintain the overall efficiency and longevity of the system. Additionally, strainers can also improve the quality of the fluid by removing impurities and ensuring a clean flow. In industries where cleanliness and precision are paramount, such as in pharmaceutical or food processing plants, the use of strainers is especially important to meet regulatory standards and ensure product quality. Overall, incorporating a strainer into a piping system is a simple yet effective way to safeguard equipment, optimize performance, and reduce maintenance costs in the long run.

Benefits of Using a Strainer

- Protects downstream equipment from damage

Strainers protects downstream equipment from damage caused by debris or contaminants in the fluid stream. Strainers also help to maintain consistent flow rates and pressure levels, which is essential for the proper functioning of various industrial processes. By using strainers, companies can extend the lifespan of their equipment and reduce the risk of costly downtime. Additionally, strainers can improve the overall quality of the end product by removing impurities before they can cause issues. Overall, the benefits of using a strainer in industrial applications are numerous and can greatly impact the efficiency and effectiveness of operations.

- Improves system performance by removing debris

Improves system performance by removing debris and preventing clogs in pipes and equipment. This not only helps to prevent damage to machinery, but also ensures that systems operate at their optimal levels. By maintaining a clean and efficient system, companies can save on maintenance costs and increase productivity. Furthermore, strainers can also help to protect sensitive equipment from damage, such as pumps and valves, by filtering out particles that could cause harm. In conclusion, the use of strainers in industrial applications is a crucial aspect of ensuring smooth and efficient operations.

– Extends the Lifespan of Piping Systems

Regular maintenance and cleaning of strainers can also help to extend the lifespan of piping systems, reducing the need for costly replacements. By investing in high-quality strainers and regularly monitoring their performance, companies can ensure that their operations run smoothly and efficiently for years to come. Additionally, proper strainer maintenance can also help to improve overall safety in the workplace, as clogs and blockages in pipes can pose serious hazards to employees. Overall, the use of strainers in industrial applications is essential for maintaining a safe, efficient, and cost-effective operation.

Installation and Maintenance

Proper installation techniques and regular maintenance of strainers are crucial for ensuring their effectiveness. Installing strainers correctly can prevent leaks and ensure optimal performance. It is important to follow manufacturer guidelines and recommendations when installing strainers to avoid any issues down the line. Additionally, regular maintenance such as cleaning and inspecting strainers can help prevent potential problems and prolong their lifespan. By investing time and effort into proper installation and maintenance, companies can maximize the benefits of using strainers in their industrial operations.

– Regular Maintenance Requirements

Regular maintenance requirements include checking for buildup or blockages, replacing worn-out parts, and testing for proper functionality. It is also crucial to keep a record of maintenance activities and schedule routine inspections to stay ahead of any potential problems. By staying on top of maintenance tasks, companies can ensure that their strainers continue to operate effectively and efficiently, minimizing the risk of unexpected failures or disruptions in operations. Overall, investing time and resources into proper maintenance practices can greatly benefit the overall performance and reliability of industrial strainers.

– Common Issues to Watch Out For

Common issues to watch out for when maintaining industrial strainers include corrosion, clogging, and leaks. Corrosion can weaken the structure of the strainer and lead to leaks, while clogging can reduce flow rates and efficiency. Regular inspections can help identify these issues early on and prevent more serious problems from occurring. Additionally, checking for leaks and repairing them promptly can help maintain the integrity of the system and prevent contamination of the product being filtered. By addressing these common issues proactively, companies can extend the lifespan of their strainers and avoid costly downtime.

Choosing the Right Strainer for Your System

– Considerations When Selecting a Strainer

When selecting a strainer for your system, consider the type of material being filtered, the flow rate required, the pressure rating needed, and the size of particles being removed. It is important to choose a strainer that is compatible with the specific needs of your system to ensure optimal performance and longevity. Additionally, considering factors such as ease of maintenance and access for cleaning can also help streamline operations and reduce downtime. Ultimately, selecting the right strainer for your system is crucial in maintaining efficiency and preventing costly repairs in the long run.

– Matching the Strainer to Your System’s Specifications

Matching the strainer to your system’s specifications will help ensure that it operates smoothly and effectively. By taking into account all the necessary factors, such as flow rate, pressure rating, and particle size, you can avoid potential issues and keep your system running at its best. Regular maintenance and cleaning of the strainer will also extend its lifespan and prevent any clogs or malfunctions. Overall, investing time in selecting the right strainer now will pay off in the future by saving you time and money on repairs and replacements.

– Consulting with a Professional

Consulting with a professional for guidance and advice can also be beneficial in determining the best strainer for your specific system. Their expertise can help you make the most informed decision, ensuring that your system operates efficiently and effectively. Additionally, staying up-to-date on industry standards and advancements in strainer technology can also help you make informed choices when selecting a strainer for your system. By investing in the right strainer and staying proactive with maintenance, you can optimize the performance of your system and avoid any potential issues down the line.

Conclusion

To wrap things up, choosing the right strainer for your piping system is essential for maintaining its performance and longevity. By consulting experts and keeping up with industry advancements, you can make informed decisions that will benefit your system. A good-quality strainer not only prevents debris and contaminants from causing damage but also saves you from costly repairs and downtime. Regular maintenance, including inspection and cleaning, ensures that your strainer works effectively and keeps your system running smoothly. In essence, investing in a reliable strainer is a smart move for any facility, helping to protect your equipment and ensure efficient operations.