What are the key differences between Stainless Steel 302, 304, 304L, 316, 316L, 316Ti, 314, 321, 430L, and 434A Redraw Wires?

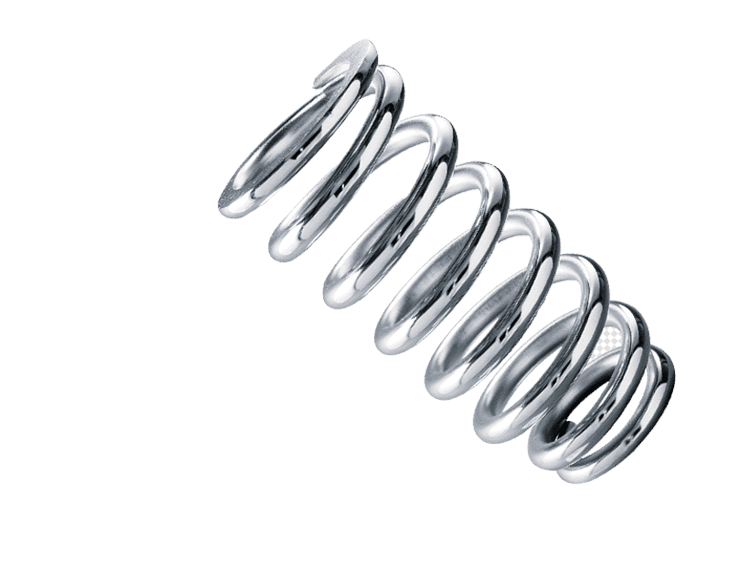

Stainless Steel 302, 304, 304L, 316, 316L, 316Ti, 314, 321, 430L, and 434A Redraw Wires are distinct variants within the stainless steel family, each exhibiting unique properties tailored to specific applications. Stainless Steel 302 offers excellent corrosion resistance and is commonly used in applications requiring high tensile strength. Meanwhile, Stainless Steel 304 is renowned for its versatility and corrosion resistance, making it suitable for various industry applications. The addition of low carbon content characterizes Stainless Steel 304L, ensuring better weldability and preventing sensitization issues.

Stainless Steel Redraw Quality Wire, stainless steel Re-draw wires, AISI 302 Stainless Steel Wires Redraw, Redraw Wire Supplier In Mumbai, India.

Stainless Steel 316 contains molybdenum, enhancing its corrosion resistance, particularly in chloride environments. Stainless Steel 316L, a low-carbon version of 316, exhibits improved weldability and is widely used in chemical processing and marine applications. Stainless Steel 316Ti, with added titanium, provides increased resistance to sensitization during welding and elevated temperatures.

Stainless Steel 314 is known for its high-temperature strength and oxidation resistance, making it suitable for furnace and heat-treatment applications. Stainless Steel 321 contains titanium, offering improved resistance to intergranular corrosion, especially in high-temperature environments.

India

India Russia

Russia Portugal

Portugal UK

UK Malaysia

Malaysia Kuwait

Kuwait Oman

Oman United States

United States Morocco

Morocco Saudi Arabia

Saudi Arabia Canada

Canada Australia

Australia Costa Rica

Costa Rica Singapore

Singapore Qatar

Qatar Japan

Japan Italy

Italy Iran

Iran China

China Thailand

Thailand South Korea

South Korea UAE

UAE Turkey

Turkey Egypt

Egypt Germany

Germany Philippines

Philippines Vietnam

Vietnam Kazakhstan

Kazakhstan Sri Lanka

Sri Lanka Greece

Greece Netherlands

Netherlands Spain

Spain Tobago

Tobago Romania

Romania France

France Jordan

Jordan Taiwan

Taiwan Colombia

Colombia Norway

Norway Bangladesh

Bangladesh Chile

Chile Myanmar

Myanmar Hong Kong

Hong Kong Venezuela

Venezuela Indonesia

Indonesia Poland

Poland South Africa

South Africa Iraq

Iraq Tobago

Tobago Angola

Angola Cyprus

Cyprus Ukraine

Ukraine Brazil

Brazil Czechia

Czechia Nigeria

Nigeria Mexico

Mexico