Reflux valves or non-return valves are one-way directional valves which permit fluid flow in one direction only and never offer backflow, thus safeguarding pipelines and pumps. Caliper Overseas is a reliable Reflux Valve Manufacturer and Reflux Valve Supplier in India, provides superior quality valves that facilitate smooth, efficient and safe operations in numerous industries.

Reflux Valve, Reflux Valve Sewer, Reflux Valve Cost, 150mm Reflux Valve, Reflux Valve Shower, Reflux Check Valve Supplier In Mumbai, India.

These are strong-built valves, corrosion resistant and highly durable. They offer minimal pressure drop, minimal maintenance and tight sealing. Manufactured to international quality standards, each of these valves is submitted to a test of high temperature and pressure durability and performance. They come in different sizes and materials for use in different pipeline systems and applications needs in various industries.

For reliable reflux valves needs, call us today!

Reflux Check Valve Weight, Advance Reflux Check Valve, Reflux Check Valve Dimensions, Reflux Check Valve Suppliers, Flanged End Reflux Check Valve, Non-Return Reflux Valve, Reflux Valve Single Door, Reflux Valve Multi Door, Reflux Check Valve Exporter In India.

Reflux Check Valve Specification

| Design Standards | 1S 5312 / IS: 5312 – 2 |

|---|---|

| Size Range | 40 to 700 mm (Single Door) Pressure up to PN 1.6 |

| Conforming to | IS - 5312 (Part-1) Pressure upto PN 16 Conforming to BS EN 12334 (formerly BS : 5153) |

| Pressure Rating | PN 0.6, PN 1.0, PN 1.6 |

| Flanged ends | as per IS:1538 PN-1.6 (FF) |

| Maximum Working Pressure | 16 Bar |

| Maximum Working Temperature | 45°C |

| Application & uses | Water distribution Water treatment Wastewater Dams Power plants Industry |

High Pressure Reflux Check Valve, Heavy Duty Reflux Check Valve, Welded End Reflux Valve, Industrial Reflux Valve, High-Quality Reflux Check Valve, Reflux Check Valve Stockist In Mumbai.

“View Reflux Check valve pressure rating, Contact us today to know Reflux valve best offers & prices.”

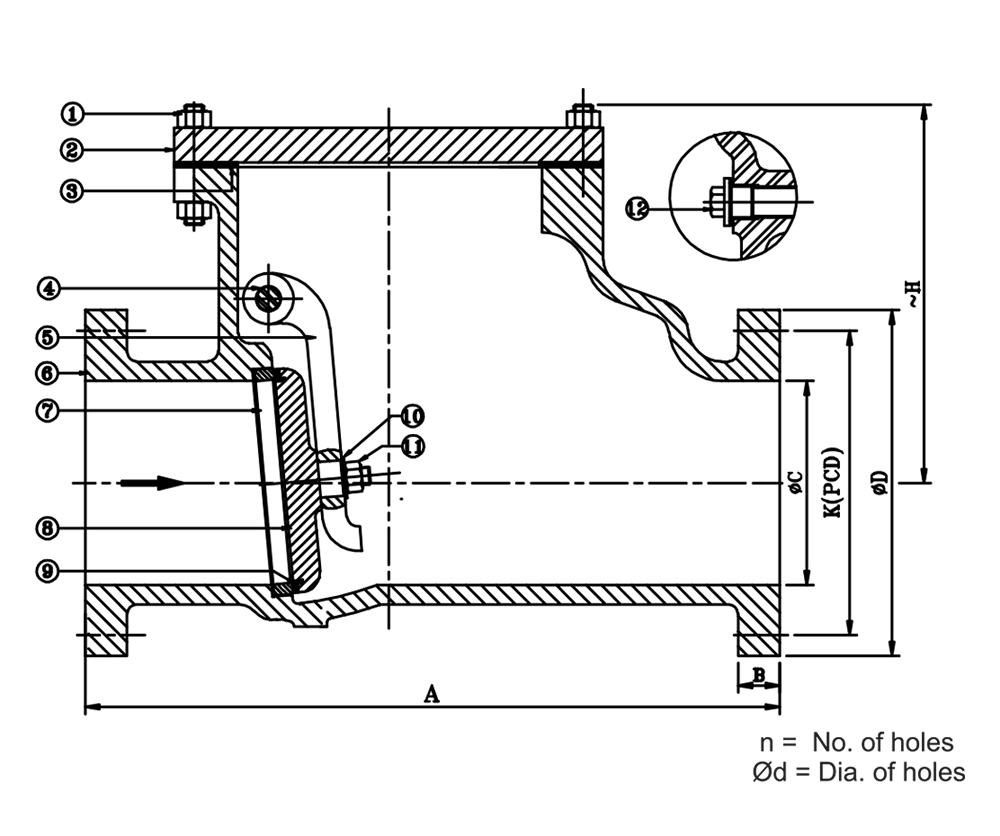

| P. NO. | NAME OF PART | MATERIAL | SPECIFICATION |

|---|---|---|---|

| 1 | STUDS & NUTS | CARBON STEEL | IS 1363 |

| 2 | COVER | CAST IRON | IS 210 Gr. FG200 |

| 3 | GASKET | C.N.A.F/RUBBER | IS 638 TYPEB |

| 4 | HINGE PIN | H.T. BRASS | IS 6912 FHTB1 |

| 5 | HINGE | CAST IRON | IS 210 Gr. FG200 |

| 6 | BODY | CAST IRON | IS 210 Gr. FG200 |

| 7 | SEAT RING | LEADED IN BRONZE | IS 318 LTB2 |

| 8 | DISC | CAST IRON | IS 210 Gr. FG200 |

| 9 | DISC RING | LEADED IN BRONZE | IS 318 LTB2 |

| 10 | WASHER | LEADED IN BRONZE/BRASS | IS 318 LTB2 |

| 11 | NUT | H.T. BRASS | IS 6912 FHTB1 |

| 12 | SIDE PLUG | LEADED IN BRONZE | IS 318 LTB2 |

- Reflux Valve Stockist In Mumbai

- Reflux Check Valve Supplier

- Flanged End Type Reflux Check Valve

- Single Door Reflux Check Valve

- Reflux Check Valve Manufacturer

- 150# Reflux Check Valve

- Multi Door Reflux Check Valve

- PN 20 Reflux Check Valve

- Welded End Type Reflux Check Valve

- Reflux Valves Manufacturer in India

- PN 16 Reflux Check Valves

- PN 50 Reflux Check Valve

- Reflux Valve Supplier In India

- PN 100 Reflux Check Valves

- Class 300 Reflux Check Valves

- Non Return Check Valves Supplier

- More Durable Reflux Check Valves

- PN10 Reflux Check Valve

Reflux Check Valves in Distillery Plants

Reflux Check Valves in Sugar Industries

Reflux Check Valve in Process Industries

Reflux Check Valve in Power Plants

Reflux Check Valve in Refineries

Reflux Check Valve in Petrochemical Plants

Your #1 Source for Reflux Check Valve

UAE

UAE Iran

Iran South Korea

South Korea Egypt

Egypt Italy

Italy Thailand

Thailand Australia

Australia Germany

Germany Vietnam

Vietnam Singapore

Singapore Costa Rica

Costa Rica Japan

Japan Kazakhstan

Kazakhstan Kuwait

Kuwait Saudi Arabia

Saudi Arabia Malaysia

Malaysia Portugal

Portugal Philippines

Philippines Oman

Oman Qatar

Qatar Turkey

Turkey China

China India

India Morocco

Morocco United States

United States UK

UK

Canada

Canada Russia

Russia France

France Venezuela

Venezuela Norway

Norway Colombia

Colombia Ukraine

Ukraine Czechia

Czechia Poland

Poland Myanmar

Myanmar Romania

Romania Chile

Chile Netherlands

Netherlands Taiwan

Taiwan Hong Kong

Hong Kong Indonesia

Indonesia Tobago

Tobago Greece

Greece Jordan

Jordan South Africa

South Africa Bangladesh

Bangladesh Mexico

Mexico Nigeria

Nigeria Angola

Angola Spain

Spain Iraq

Iraq Cyprus

Cyprus Tobago

Tobago Brazil

Brazil Sri Lanka

Sri Lanka

Reflux Check Valve Stock Availability

Stainless Steel Reflux Valve

300# SS Reflux Check Valve, Stainless Steel Reflux Valve Exporter, Stainless Steel Reflux Valve, Flanged End Type Stainless Steel Reflux Valve, SS Reflux Check Valve, SS Reflux Check Valve Supplier, 150# SS Reflux Check Valve, Welded End Type SS Reflux Check Valve, Single Door Stainless Steel Reflux Check Valve, Multi Door SS Reflux Check Valve, Stainless Steel Reflux Check Valve Price.

Carbon Steel Reflux Valve

Flanged End Type Carbon Steel Reflux Check Valve, Multi Door CS Reflux Valve, CS Reflux Check Valve, 150# CS Reflux Check Valve, 300# CS Reflux Check Valve, Welded End Type CS Reflux Check Valve, CS Reflux Valve Supplier, Carbon Steel Reflux Check Valve Price, Carbon Steel Reflux Check Valve, Single Door Carbon Steel Reflux Valve, Carbon Steel Reflux Check Valve Exporter.

Cast Iron Reflux Valve

150# Cast Iron Reflux Check Valve, Multi Door Cast Iron Reflux Check Valve, Flanged End Type Cast Iron Reflux Check Valve, Cast Iron Reflux Valve Price, Cast Iron Reflux Check Valve Supplier, Single Door Cast Iron Reflux Valve, Cast Iron Reflux Check Valve Exporter, Cast Iron Reflux Check Valve, 300# Cast Iron Reflux Valve, Cast Iron Reflux Check Valve, Welded End Type Cast Iron Reflux Check Valve.

Alloy Steel Reflux Valve

Multi Door AS Reflux Check Valve, AS Reflux Check Valve Supplier, Welded End Type AS Reflux Valve, 300# AS Reflux Check Valve, Alloy Steel Reflux Check Valve Exporter, AS Reflux Check Valve, Flanged End Type Alloy Steel Reflux Check Valve, Single Door Alloy Steel Reflux Check Valve, Alloy Steel Reflux Check Valve, Alloy Steel Reflux Valve Price, 150# AS Reflux Check Valve.