A gate valve is a valve that controls liquid flow by lifting a gate away from the fluid path. It provides a straight-through unobstructed flow, reducing pressure drop. Caliper Overseas is a reliable gate valve manufacturer and supplier in India, supplying long-lasting and precision-made valves for different industrial uses.

Manual gate valve, Pneumatic gate valve, Electric gate valve, Gate valve diagram, Gate Valve Supplier In Mumbai, India.

These valves feature tight closing, corrosion resistance and strong construction. They are specifically designed to function reliably and can be supplied in stainless steel, alloy steel, carbon steel, brass and copper-nickel. Our valves meet international specifications such as DIN / EN, ASME / ANSI and IBR and are suitable due to compatibility and quality. Gate valves feature strong pressure endurance and smooth performance which make them a perfect choice for shut-off functions in pipeline systems and process equipment.

Contact us today to select the appropriate gate valve for your system.

Parallel Gate Valves Manufacturer, Parallel Gate Valves Suppliers, Wedge Gate Valves Stockist, Wedge-shaped Gate Valves, Gate Instrumentation Valve Supplier, Gate Valve Exporter In India.

Gate Valve Specification

| Design Standards | MSS SP 81 |

|---|---|

| Ansi Class / Rating | 150#/PN 10 |

| F to F Standard | ASME B16.10 |

| Size | 50 MM TO 600 MM |

| Ends | Wafer Lugged End, Full Lugs, Wafer Type, Flangeless |

| Valve Operation | Mannual, Pneumatic, Cylinder, Bevel Gear, Electric Motor, Chain Wheel, Lever |

| Pressure Rating | 50 mm to 300 mm –150 psi 400 mm to 450 mm –75 psi 500 mm to 600 mm –50 psi |

| End Connections | A choice of flanged, RTJ flanged or buttwelding end for piping flexibility. |

| Application & uses | Pulp & Paper Industry Cement Plant Oil Refineries Chemical & Steel Industry Sugar Industry Power Plant |

Heavy Duty Gate Valve, High Pressure Gate Valve, High-Quality Gate Valve, Pneumatic Gate Valve, Industrial Gate Valve, Gate Valve Stockist In Mumbai.

“View Gate valve pressure rating, Contact us today to know Gate valve best offers & prices.”

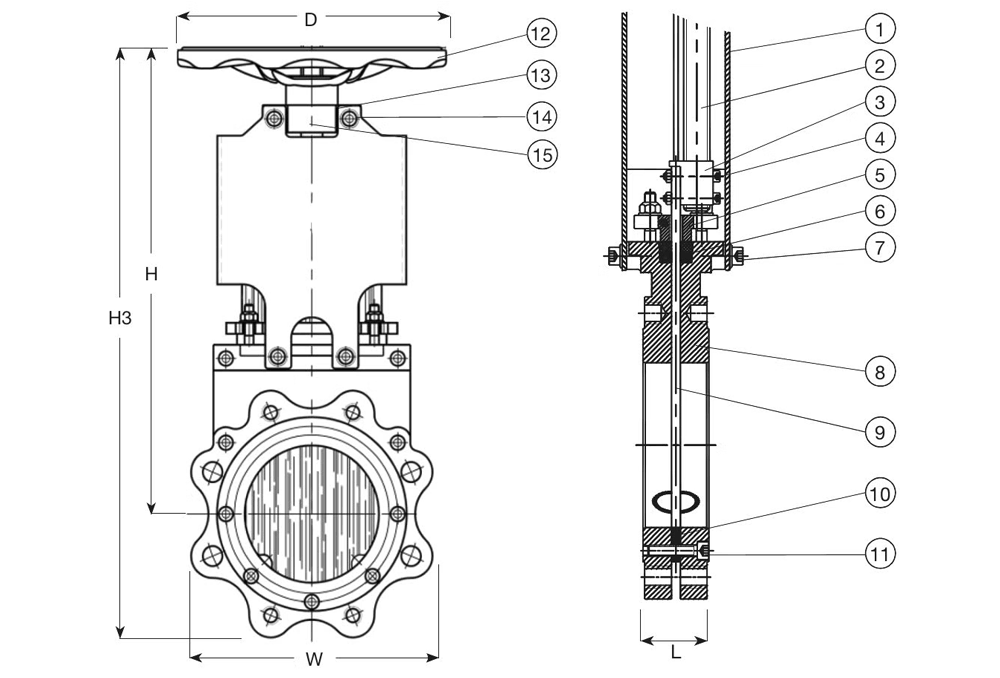

| 1. | Plate | Carbon steel |

| 2. | Stem | Stainless steel |

| 3. | Stem nut | Bronze |

| 4. | Bolt | Stainless steel A4 |

| 5. | Top packing gland | Ductile iron GJS-400-15 (GGG-40) |

| 6. | Packing | NBR + PTFE |

| 7. | Bolt | Stainless steel A4 |

| 8. | Body | Ductile iron GJS-400-15 (GGG-40) |

| 9. | Gate | Stainless steel 316 |

| 10. | U-shaped seal | Steel / NBR |

| 11. | Bolt | Stainless steel A4 |

| 12. | Handwheel | Steel |

| 13. | Washer | Stainless steel A4 |

| 14. | Bolt | Stainless steel A4 |

| 15. | Bearing | Carbon steel |

- Wafer Lugged End Gate Valve

- Square Port Knife Gate Valve

- Pneumatic Gate Valve

- Gate Valve Supplier

- Manual Gate Valve

- Gate Valve Stockist In Mumbai

- 150# Gate Valve

- Gate Valve Manufacturer

- Double Disc Single Expanding Design Gate Valve

- Seal Welded Gate Valve

- Gate Valves Manufacturer in India

- 150# Gate Valve

- More Durable Gate Valves

- Spiral Wound Type Gate Valves

- Class 300 Gate Valves

- Gate Valve Supplier In India

- Standard Flexible Wedge Design Gate Valves

- Gate Valve Supplier

- Parallel slide design Gate Valves

Gate Valves in Distillery Plants

Gate Valves in Sugar Industries

Gate Valve in Process Industries

Gate Valve in Power Plants

Gate Valve in Refineries

Gate Valve in Petrochemical Plants

Your #1 Source for Knife Gate Valve

Germany

Germany Japan

Japan Russia

Russia United States

United States Turkey

Turkey India

India Portugal

Portugal Singapore

Singapore South Korea

South Korea Qatar

Qatar Saudi Arabia

Saudi Arabia Iran

Iran UAE

UAE Costa Rica

Costa Rica Thailand

Thailand Vietnam

Vietnam Australia

Australia Philippines

Philippines Morocco

Morocco Canada

Canada Kazakhstan

Kazakhstan UK

UK

Italy

Italy China

China Egypt

Egypt Kuwait

Kuwait Oman

Oman Malaysia

Malaysia Greece

Greece Indonesia

Indonesia Taiwan

Taiwan Venezuela

Venezuela Czechia

Czechia Brazil

Brazil Colombia

Colombia Iraq

Iraq South Africa

South Africa Myanmar

Myanmar France

France Romania

Romania Chile

Chile Sri Lanka

Sri Lanka Cyprus

Cyprus Poland

Poland Angola

Angola Bangladesh

Bangladesh Spain

Spain Norway

Norway Netherlands

Netherlands Ukraine

Ukraine Tobago

Tobago Jordan

Jordan Hong Kong

Hong Kong Nigeria

Nigeria Tobago

Tobago Mexico

Mexico

Gate Valve Stock Availability

Stainless Steel Gate Valve

Stainless Steel Gate Valve Exporter, Stainless Steel Gate Valve, SS Gate Valve Supplier, Wafer Lugged End Stainless Steel Gate Valve, Stainless Steel Gate Valve Price, SS Electric Gate Valve, Stainless Steel Knife Gate Valve, 300# SS Gate Valve, 150# SS Gate Valve, SS Gate Valve, Manual SS Gate Valve.

Carbon Steel Gate Valve

Carbon Steel Gate Valve, CS Gate Valve Supplier, 300# CS Gate Valve, Wafer Lugged End Carbon Steel Gate Valve, Carbon Steel Gate Valve Exporter, CS Electric Gate Valve, Manual CS Gate Valve, CS Gate Valve, Carbon Steel Gate Valve Price, 150# CS Gate Valve, Pneumatic Carbon Steel Gate Valve.

Cast Iron Gate Valve

300# Cast Iron Gate Valve, Cast Iron Gate Valve Price, Cast Iron Gate Valve Exporter, Cast Iron Gate Valve, Pneumatic Cast Iron Gate Valve, Cast Iron Electric Gate Valve, Cast Iron Gate Valve, Cast Iron Gate Valve Supplier, Wafer Lugged End Cast Iron Gate Valve, 150# Cast Iron Gate Valve, Manual Cast Iron Gate Valve.

Alloy Steel Gate Valve

Alloy Steel Gate Valve, AS Electric Gate Valve, Alloy Steel Gate Valve Price, Manual AS Gate Valve, 150# AS Gate Valve, 300# AS Gate Valve, AS Gate Valve Supplier, Wafer Lugged End Alloy Steel Gate Valve, AS Gate Valve, Pneumatic Alloy Steel Gate Valve, Alloy Steel Gate Valve Exporter.