Sluice gate valves are critical flow control valves that control the flow of water, slurry, and other fluids through pipelines and open channels. Caliper Overseas is a reliable sluice gate valve manufacturer and supplier in India with superior valves constructed according to DIN 3352 standards. Sluice gate valves are used extensively in water treatment plants, irrigation systems, sewage lines and industrial processes where tight shut-off and smooth flow are essential.

Sluice Valve Price, Sluice Gate Valve, Sluice Valve Function, CI Sluice Valve, DI Sluice Valve, Sluice Gate Valve Supplier In Mumbai, India.

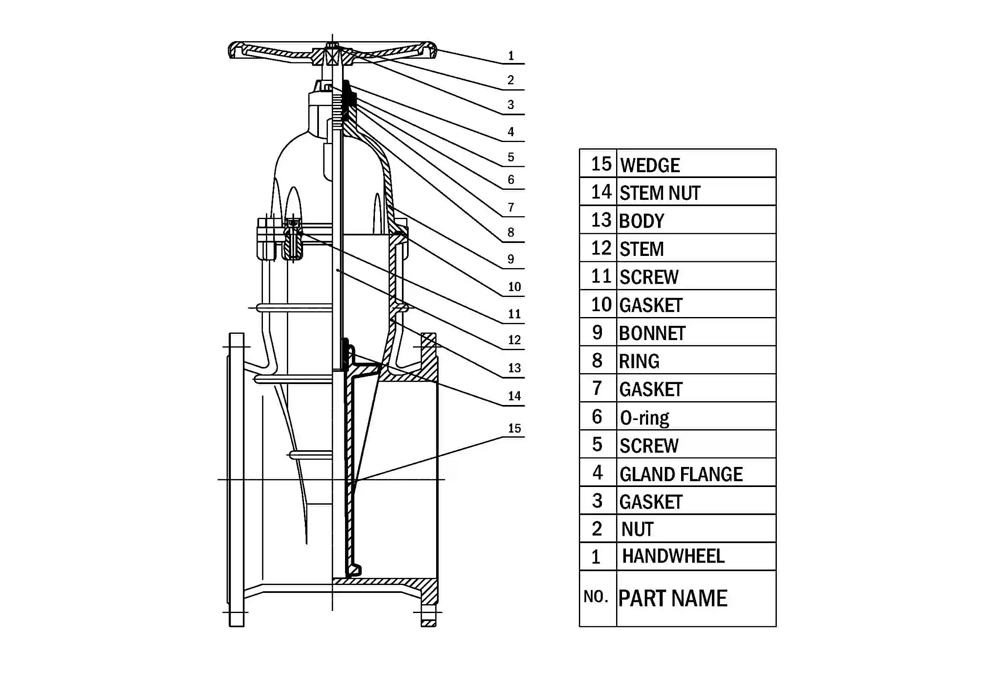

Designed to function and endure, sluice gate valves are constructed with a sturdy body design, corrosion-resistant finishes and a rising or non-rising spindle mechanism for simple operation. These valves ensure low pressure drop, long service life and assured sealing even in harsh conditions. With different sizes and pressure ratings, the valves provide accurate control and low maintenance.

Contact us today for efficient sluice gate valves designed around your requirements.

Metal Seated Sluice Gate Valve, Non-Rising Spindle Type Sluice Gate Valve, Rising Spindle Type Sluice Gate Valves, Sluice Gate Valve With Adaptor, Flanged End Sluice Gate Valve, Sluice Gate Valve Suppliers, Sluice Gate Valve Exporter In India.

Sluice Gate Valve Specification

| Design Standards | DIN 3352 |

|---|---|

| Size Range | NPS 2 to NPS 24, 40 mm to 1800 mm |

| Class Range | PN10/16/150LB |

| Pressure Rating | IS : 14846 PN 1.0 & IS : 14846 PN 1.6 |

| Spindle | St. Steel IS : 6603 Gr. 12Cr12 |

| Stem Nut | Leaded Tin Bronze IS: 318 Gr. LTB - 2 |

| Temperature Withstand | Up to 180° C |

| Turbidity | Up to 5000 ppm and temperature up to 45° C |

| Application & uses | Pulp & Paper Industry Cement Plant Oil Refineries Chemical & Steel Industry Sugar Industry Power Plant |

Rising Stem Sluice Gate Valve, High Pressure Sluice Gate Valve, Industrial Sluice Gate Valve, Heavy Duty Sluice Gate Valve, High-Quality Sluice Gate Valve, Sluice Gate Valve Stockist In Mumbai.

“View Sluice Gate valve pressure rating, Contact us today to know Sluice Gate valve best offers & prices.”

- Cap Operated Sluice Valve

- Solid Wedges Sluice Gate Valve

- Sluice Gate Valve Supplier

- Rising Spindle Type Sluice Gate Valve

- 150# Sluice Gate Valve

- Sluice Gate Valve Manufacturer

- Flanged End Sluice Gate Valve

- Rising Stem Sluice Gate Valve

- Inclined Disc Designs Sluice Gate Valve

- Sluice Gate Valve Stockist In Mumbai

- 150# Sluice Gate Valve

- Sluice Gate Valves Manufacturer in India

- Non-Rising Stem Sluice Gate Valves

- Split Wedge Sluice Gate Valves

- Sluice Valve Supplier

- Flexible Wedges Sluice Gate Valves

- More Durable Sluice Gate Valves

- Sluice Gate Valve Supplier In India

- Class 300 Sluice Gate Valves

- 600# Sluice Gate Valves

Sluice Gate Valves in Distillery Plants

Sluice Gate Valves in Sugar Industries

Sluice Gate Valve in Process Industries

Sluice Gate Valve in Power Plants

Sluice Gate Valve in Refineries

Sluice Gate Valve in Petrochemical Plants

Your #1 Source for Sluice Gate Valve

Costa Rica

Costa Rica Egypt

Egypt Saudi Arabia

Saudi Arabia Oman

Oman Singapore

Singapore Canada

Canada Portugal

Portugal Turkey

Turkey South Korea

South Korea Japan

Japan Morocco

Morocco Kuwait

Kuwait Italy

Italy UK

UK

Iran

Iran UAE

UAE Qatar

Qatar Vietnam

Vietnam Malaysia

Malaysia Russia

Russia Philippines

Philippines Kazakhstan

Kazakhstan United States

United States India

India Thailand

Thailand China

China Australia

Australia Germany

Germany Brazil

Brazil Netherlands

Netherlands Poland

Poland Bangladesh

Bangladesh Iraq

Iraq Romania

Romania Tobago

Tobago Hong Kong

Hong Kong Spain

Spain Tobago

Tobago Taiwan

Taiwan Venezuela

Venezuela South Africa

South Africa Myanmar

Myanmar Nigeria

Nigeria Czechia

Czechia Angola

Angola Ukraine

Ukraine Indonesia

Indonesia Norway

Norway Chile

Chile Mexico

Mexico Greece

Greece Cyprus

Cyprus Jordan

Jordan Colombia

Colombia France

France Sri Lanka

Sri Lanka

Sluice Gate Valve Stock Availability

Stainless Steel Sluice Gate Valve

150# SS Sluice Gate Valve, Flanged End Stainless Steel Sluice Gate Valve, Stainless Steel Sluice Gate Valve Exporter, SS Sluice Gate Valve Supplier, SS Non-Rising Spindle Type Sluice Gate Valve, Rising Stem SS Sluice Gate Valve, SS Sluice Gate Valve, Stainless Steel Sluice Gate Valve Price, 300# SS Sluice Gate Valve, Stainless Steel Sluice Gate Valve, Stainless Steel Metal Seated Sluice Gate Valve.

Carbon Steel Sluice Gate Valve

Carbon Steel Sluice Gate Valve, Rising Spindle Type Carbon Steel Sluice Gate Valve, Flanged End Carbon Steel Sluice Gate Valve, CS Non-Rising Spindle Type Sluice Gate Valve, CS Sluice Gate Valve Supplier, 300# CS Sluice Gate Valve, Carbon Steel Sluice Gate Valve Price, Rising Stem CS Sluice Gate Valve, 150# CS Sluice Gate Valve, Carbon Steel Sluice Gate Valve Exporter, CS Sluice Gate Valve.

Cast Iron Sluice Gate Valve

Rising Stem Cast Iron Sluice Gate Valve, Cast Iron Sluice Gate Valve, Cast Iron Sluice Gate Valve Supplier, 300# Cast Iron Sluice Gate Valve, Cast Iron Non-Rising Spindle Type Sluice Gate Valve, Cast Iron Sluice Gate Valve Price, 150# Cast Iron Sluice Gate Valve, Flanged End Cast Iron Sluice Gate Valve, Cast Iron Sluice Gate Valve, Cast Iron Sluice Gate Valve Exporter, Rising Spindle Type Cast Iron Sluice Gate Valve.

Alloy Steel Sluice Gate Valve

Alloy Steel Sluice Gate Valve Price, Flanged End Alloy Steel Sluice Gate Valve, Alloy Steel Sluice Gate Valve Exporter, AS Sluice Gate Valve Supplier, Rising Stem AS Sluice Gate Valve, Alloy Steel Sluice Gate Valve, Rising Spindle Type Alloy Steel Sluice Gate Valve, AS Non-Rising Spindle Type Sluice Gate Valve, 300# AS Sluice Gate Valve, 150# AS Sluice Gate Valve, AS Sluice Gate Valve.